Name Specification: PEM NUT M6

Reference standard: JIS/ANSI/DIN/BSI

Surface Treatment: DEGREASE

Salt spray time: over 12 hours / HIGH SALT SPRAY: 12H

Product Specifications: M6.0*PITCH 1.0

Origin: CHINA

Material: SUS

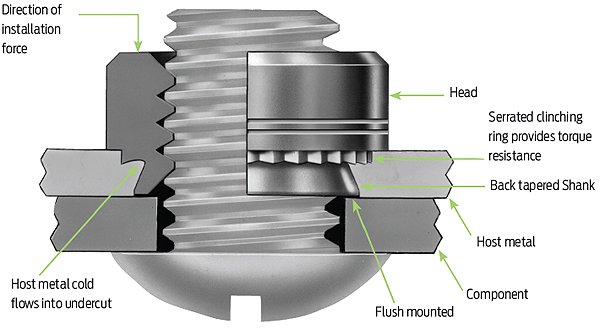

PEM self-clinching nut is a fastener designed for thin metal plates. The nut is embedded in the metal plate by cold pressing to form a reliable threaded connection. It can provide high-strength threaded connection on thinner plates, avoiding material damage or installation complexity problems that may be caused by traditional welded nuts or riveted nuts.

Material selection

The material selection of PEM self-clinching nuts mainly depends on the application environment and strength requirements. Common materials include:

Carbon steel (galvanized/nickel-plated): suitable for general metal plates, low cost, moderate strength, suitable for most industrial applications.

Stainless steel (SUS304, SUS316): Strong corrosion resistance, suitable for special environments such as high humidity, high temperature, chemical industry, such as medical, food processing and marine engineering.

Aluminum alloy: suitable for industries with high weight requirements, such as aerospace and precision electronic equipment, which can reduce overall weight and maintain good structural strength.

Features of PEM self-clinching nuts

Low plate thickness applicability: can be used for metal sheets above 0.5mm, providing high-strength threaded connection.

No welding required: cold pressing is used to install, avoiding the influence of thermal stress of welding.

Automated installation support: suitable for mass production, can be used in automated assembly lines, and improve production efficiency.

Anti-loosening design: after embedding, a reliable threaded connection is formed, which is resistant to vibration and not easy to loosen.

High durability: after embedding, it becomes part of the sheet and will not fall off after long-term use.

Advantages of PEM self-locking nuts

High-strength connection

Through plastic deformation, the metal sheet surrounds the embossed part of the nut, making it firmly fixed and providing strong pull-out and torque resistance.

Applicable to ultra-thin sheets

Traditional welding nuts are prone to welding deformation or penetration on thin plates. PEM nuts can form high-strength connections on extremely thin plates and are widely used in precision equipment.

Easy installation

The cold pressing embedding method is adopted, and no additional tools or welding equipment are required, which reduces labor costs and improves assembly efficiency.

Strong corrosion resistance

After using stainless steel or surface protection treatment, it can adapt to harsh environments such as humidity and chemical corrosion, ensuring long-term and stable use.

Lightweight design

Applicable to automotive, aerospace and other fields, it can reduce the overall weight of the equipment while ensuring the connection strength.

Surface treatment

PEM self-locking nuts have various surface treatment methods, the main purpose of which is to improve corrosion resistance and mechanical properties:

Galvanizing: Improve corrosion resistance and prevent rust, commonly used in general industrial applications.

Nickel plating: Enhance oxidation resistance and improve wear resistance, suitable for high-precision equipment.

Dacromet coating: Has excellent salt spray corrosion resistance, suitable for automobiles, oceans and high humidity environments.

Phosphating: Provides good wear resistance and can be used as a base layer for paint or coating to improve adhesion.

Black oxidation treatment: Provides certain corrosion resistance while meeting specific appearance requirements, such as military equipment.

Mechanical performance requirements

Pulling resistance

Ensure that the nut will not fall off the metal plate under high load, and common specifications can withstand tensile forces of 50N to 500N or more.

Torque resistance

Sufficient anti-rotation ability must be provided to prevent the nut from rotating when tightening the bolt, usually requiring a torque of more than 10Nm.

Durability

After tens of thousands of loading and unloading, it still maintains stable thread connectivity, suitable for equipment that requires frequent maintenance.

Scope of use

Due to the high strength, durability and lightweight characteristics of PEM self-locking nuts, it is widely used in the following industries:

Electronic equipment

Suitable for PCB fixing, metal housing connection, etc., providing high-precision fastening solutions.

Automobile manufacturing

Self-locking nuts are used in body, engine bracket, battery box and other parts to improve seismic resistance and installation efficiency.

Aerospace

Fields that require lightweight and high-strength connections, such as cabin interiors, instrumentation equipment, etc.

Medical equipment

Use stainless steel or anti-corrosion materials to ensure long-term stable operation of equipment, such as surgical equipment, testing instruments, etc.

Communication equipment

Used for metal housing installation of 5G base stations, server cabinets, and optical fiber equipment to ensure long-term stable signal connection.

Rail transportation

High-speed trains and subway car connection components provide stable seismic fastening solutions.

Household appliances

Suitable for fastening of metal housing structural parts such as refrigerators, air conditioners, and washing machines.

PEM self-locking nut is an efficient and stable metal sheet fastener with high strength, corrosion resistance and easy installation. It can be made of carbon steel, stainless steel or aluminum alloy, and can be enhanced by surface treatment such as galvanizing, nickel plating, Dacromet, etc. It is widely used in electronic equipment, automobile, aerospace, medical equipment and other industries to provide stable threaded connection for thin plates. It is an indispensable and important fastener in modern manufacturing.

1. We have more than 20 years of experience in exporting to many countries for example America.Japan.Korea.Germany.France.England etc. In fact, we have 20 years of production experience. When the drawings are confirmed, we will provide customers with professional information to make product assembly smoother.

2. Our company have ISO9000.

3. We can give Proposing Solutions and help our customer to solve any fastner system problem.

4.We can reply you price within 2 hours.

5. We can produce samples for you in 5-7 days.

6. We can give you drawings within 2 hours.

7. Working with us can save your time and money.

8.We can confirm 100% quality in diameter and tolerance.

9.More than 90% are returned customers.

10.We not only produce and sell products ,we also can offer you help in China as friend .

11.I would like to help you to reach your dream in my ability ,give me chance is giving yourself chance.

Our logistics information exchange :

1. What types of PEM self-locking nuts can you provide?

We provide standard, extended, through-hole, blind, floating, self-locking and other PEM self-locking nuts for different application scenarios.

2. Can it be customized according to our drawings or specifications?

Yes, we can make non-standard customization according to the drawings, dimensions and tolerance requirements provided by customers, and provide samples for confirmation.

3. What materials are suitable for plates?

PEM self-locking nuts are suitable for metal materials such as aluminum plates, stainless steel plates, carbon steel plates, and copper plates. Customers need to provide the material and thickness of the plate in order to select the appropriate model.

4. What are the options for your nut materials?

We provide carbon steel, stainless steel (SUS304, SUS316), aluminum alloy, brass and other materials, which can be selected according to the use environment and strength requirements.

5. What are the options for surface treatment?

Optional galvanizing (white zinc, blue zinc, black zinc), nickel plating, tin plating, chrome plating, Dacromet, oxidation treatment, stainless steel color, etc. The specific surface treatment can be customized according to the requirements of corrosion resistance and appearance.

6. How is your thread accuracy?

Our threads can reach 6H level accuracy (according to ISO standards). If there are higher requirements, precision thread customization can be provided.

7. What is the minimum installation plate thickness of self-locking nuts?

Different types of nuts are suitable for plates of different thicknesses. The common minimum plate thickness is 0.5mm-1.0mm. Suitable models can be recommended according to customer needs.

8. Can you provide a load-bearing capacity test report for nuts?

Yes, we can provide quality inspection reports such as torque test and axial pull-out force test to ensure that the nuts meet industry standards.

9. Is there a discount for large-volume orders?

Yes, we provide a tiered price discount. The larger the order quantity, the more favorable the unit price. You can contact us for a specific quote.

10. How long is the delivery cycle?

Standard models are usually available for delivery in 3-7 days, and customized products take 2-4 weeks depending on the complexity. Please consult the sales team for specific delivery time.

11. What payment methods do you support?

We accept bank transfer (T/T), letter of credit (L/C), PayPal, etc. Specific payment terms are negotiable.

12. What are the shipping methods?

We support logistics methods such as express, air and sea transportation. We can arrange transportation according to customer needs and provide tracking information.

If you have more questions, please contact us for detailed information!

Dongguan Qisheng Metal Technology Co., Ltd. is a professional manufacturer of screws and nuts and other fastener products integrating R&D, production, processing and sales. The company is located in the famous manufacturing city in China-Dongguan City, Guangdong Province. The company covers an area of 3,000 square meters.

Specializing in the production of special precision screws and nuts of various standards such as Chinese standard GB, Japanese standard JIS, British BS, American ANSI and ISO. Our equipment is advanced. At present, the smallest screw diameter that our company can produce is 0.4mm, the shortest is 0.4mm, and the longest is 300CM. The materials used are stainless steel SUS304 /SUS410/SUS 430 /SUS620, etc., red copper H95, brass C2700, aluminum 6061, titanium TI 04, etc.

Our products can meet the environmental testing standards of the European Union-ROHS, the United States–California 65 standard, Japan-SONY00259 etc., and even more stringent testing standards. At present, our salt spray test standard can reach up to 2000 hours, and the surface hardness can reach up to HV2000.

Our business policy is to serve every customer with the highest quality and fastest speed.

Please feel free to contact us if necessary.