Name Specification: PEM NUT M6

Reference standard: JIS/ANSI/DIN/BSI

Surface Treatment: DEGREASE

Salt spray time: over 12 hours / HIGH SALT SPRAY: 12H

Product Specifications: M6.0*PITCH 1.0

Origin: CHINA

Material: SUS

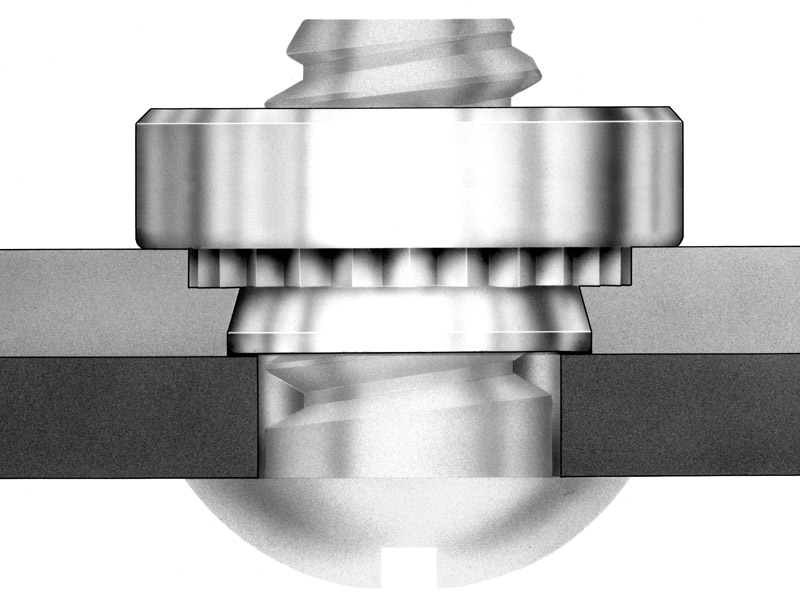

What is M6 Self Clinching Nut?

M6 Self Clinching Nut is a fastener used on thin metal sheets, designed to fix the nut to the substrate by mechanical pressure. It is usually made of high-strength materials (such as stainless steel, carbon steel, aluminum alloy, etc.), with a hexagonal or round shape and an internal thread size of M6. It is designed to form a strong connection point by pressing into the thin sheet metal during installation, without the need for additional thread cutting or welding.

The role of M6 Self Clinching Nut

M6 self-embedded nut is mainly used to provide a removable threaded connection, suitable for thin metal sheets where full thread cutting is not possible or required. During the assembly process, by pressing the nut into the metal sheet, it will produce a self-locking fastening effect on the metal surface, capable of withstanding high torque and tension. Its main functions are:

Provide a strong and reliable connection point to avoid damage to the metal sheet.

Simplify the assembly process without welding, nailing or pre-cutting threads.

Support reusable threaded connections and reduce thread wear.

Suitable for thin sheet metal, especially when installation space is limited.

Features of M6 Self Clinching Nut

High load-bearing capacity: M6 self-embedded nuts can withstand large torque and tension, suitable for high-load applications.

No thread processing required: No need to pre-cut threads on the metal plate during installation, reducing processing time and cost.

Simplified installation: The installation process is simple, just use a pressure tool to press the nut into the metal plate.

High-strength material: Self-embedded nuts are usually made of corrosion-resistant and wear-resistant materials to ensure their reliability in long-term use.

Precise positioning: It can ensure accurate installation position and ensure the consistency and reliability of the connection.

Applicable to thin plates: Especially suitable for metal plates with smaller thickness, no special deep hole drilling is required.

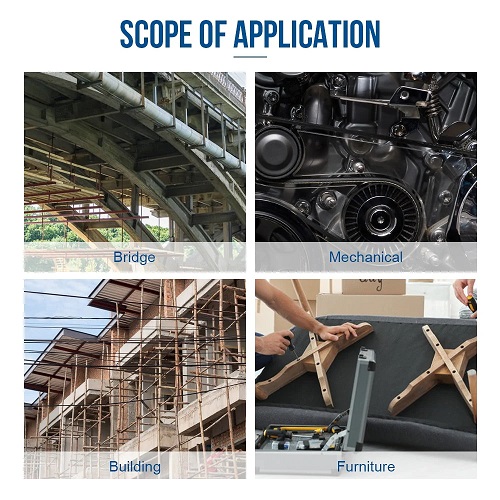

Scope of application of M6 Self Clinching Nut

M6 self-embedded nuts are widely used in various industries, especially for thin metal sheet assembly with high requirements for connection strength and reliability. Common application areas include:

Electronic equipment: used for the connection and fixation of electrical housings, especially those that require high-density components and space.

Automotive industry: suitable for the assembly of body panels and interior parts.

Electromechanical products: used for the assembly of thin metal structures such as chassis, housings, panels, etc.

Aerospace: suitable for use in the connection of precision equipment such as aviation equipment and spacecraft components.

Home appliance industry: commonly used for the assembly of housings, brackets and other components of home appliances.

M6 Self Clinching Nut is an efficient and reliable fastener solution for applications that require nuts to be fixed on thin metal plates. It provides a high-strength and durable connection effect through self-embedding technology, reducing traditional processing and assembly work. Due to its easy installation, low cost and wide range of applications, it plays an irreplaceable and important role in many industries.

FAQ

What is the M6 Self Clinching Nut? How is it different from ordinary nuts?

The M6 Self Clinching Nut is a self-embedded nut designed for thin metal plates. It presses the nut into the metal surface through mechanical pressure to form a strong threaded connection point. Unlike ordinary nuts, it does not require pre-cut threads on the metal plate, but is fixed by pressing into the metal plate, with strong load-bearing capacity and durability.

How to install the M6 Self Clinching Nut?

When installing the M6 self-embedded nut, first align the nut with the predetermined position of the metal plate, and then use a special pressure tool to press it into the metal plate. Through pressure, the nut will be firmly combined with the metal plate to form a strong self-locking connection.

How much load can the M6 Self Clinching Nut withstand?

The M6 self-embedded nut has a high load-bearing capacity and can withstand relatively large tension and torque. The specific load-bearing capacity will be affected by factors such as the nut material, the size of the mounting hole, and the thickness of the metal plate. It can usually withstand tens to hundreds of Newtons of tension.

Can I install the M6 Self Clinching Nut on an existing sheet metal?

Yes, the M6 Self Clinching Nut is designed to be installed on thin sheet metal, especially for sheet metal that has already been processed, without the need for additional thread cutting or welding. This makes it very popular in modern manufacturing, especially in environments where space is limited or processing is complex.

What sheet metal materials are suitable for the M6 Self Clinching Nut?

The M6 Self Clinching Nut is suitable for a variety of metal materials, including stainless steel, aluminum alloy, carbon steel, etc. The thickness and hardness of sheet metal of different materials may affect the installation effect of the nut, so the characteristics of the sheet metal need to be considered when selecting the nut.

After installing the M6 Self Clinching Nut, can it be removed?

Yes, the M6 Self Clinching Nut provides a removable threaded connection. During the assembly process, the nut is pressed into the sheet metal to form a stable connection, and the subsequent removal can still be carried out by removing the screws, and the nut itself will usually not loosen or damage.

What precautions should be taken when using the M6 Self Clinching Nut?

When using M6 self-clinching nuts, you need to pay attention to the following points:

Make sure the thickness and hardness of the metal plate are suitable for the installation of self-clinching nuts.

Check the size of the mounting hole before installation to ensure that it matches the nut.

Use the appropriate pressure tool for installation to ensure the firmness of the nut.

In high-load applications, consider the material's load-bearing capacity and avoid overloading.

What are the advantages of M6 Self Clinching Nut compared to welding nuts?

Compared with welding nuts, M6 self-clinching nuts have several advantages:

Easy installation: No welding equipment is required, and the installation process is simple and quick.

Suitable for thin plates: No pre-thread cutting is required, which is suitable for thin sheet metal.

Reduced processing time and cost: Compared with traditional welding nuts, material handling and equipment investment are reduced.

Repeatable disassembly: Compared with welding nuts, the connection of self-clinching nuts can be easily disassembled and replaced.

Is M6 Self Clinching Nut suitable for high temperature environments?

The high temperature resistance of M6 self-clinching nuts depends on their material. For example, self-clinching nuts made of stainless steel or other high-temperature resistant alloy materials can withstand higher operating temperatures and are suitable for high temperature environments. However, in a particularly high temperature environment, it is crucial to choose a nut made of the right material.

How long is the service life of the M6 Self Clinching Nut?

The service life of the M6 Self Clinching Nut depends on many factors, such as material type, installation quality, and working environment (such as temperature, humidity, corrosiveness, etc.). Generally speaking, self-clinching nuts made of high-quality materials can maintain stability and reliability for a long time under normal use.

1. We have more than 20 years of experience in exporting to many countries for example America.Japan.Korea.Germany.France.England etc. In fact, we have 20 years of production experience. When the drawings are confirmed, we will provide customers with professional information to make product assembly smoother.

2. Our company have ISO9000.

3. We can give Proposing Solutions and help our customer to solve any fastner system problem.

4.We can reply you price within 2 hours.

5. We can produce samples for you in 5-7 days.

6. We can give you drawings within 2 hours.

7. Working with us can save your time and money.

8.We can confirm 100% quality in diameter and tolerance.

9.More than 90% are returned customers.

10.We not only produce and sell products ,we also can offer you help in China as friend .

11.I would like to help you to reach your dream in my ability ,give me chance is giving yourself chance.

Our logistics information exchange :

What should I pay attention to when installing M6 PEM Fasteners?

When installing M6 PEM Fasteners, make sure that the substrate hole diameter matches the outer diameter of the fastener. The hole size should be accurate to ensure that the fastener can be pressed in securely. If the hole diameter is too large or too small, it may lead to unstable installation. In addition, make sure that the pressing process is properly controlled to avoid damage to the substrate or deformation of the fastener.

Are M6 PEM Fasteners suitable for all types of materials?

M6 PEM Fasteners are generally suitable for metal materials (such as steel, aluminum), plastics and composite materials. However, the hardness, density and thickness of different materials will affect their installation effect and fastening performance. For softer materials, it is recommended to choose PEM Fasteners with special designs to ensure the firmness of the connection.

How much load can M6 PEM Fasteners withstand?

M6 PEM Fasteners are designed to withstand medium loads, and the specific load-bearing capacity depends on the type, thickness and hardness of the substrate. They are suitable for use in automotive, electronics, aerospace and other fields, especially in applications where high-strength connections are required but space is limited. When choosing, make sure to choose the right fastener according to the actual load requirements.

Are PEM Fasteners suitable for high temperature environments?

The temperature resistance of M6 PEM Fasteners depends on their materials and surface treatment. Common steel or aluminum fasteners perform well in medium temperature environments, but if the application environment temperature is high (such as up to 150°C or higher), it is recommended to choose a surface treatment with high temperature resistance or a special high temperature material version to ensure connection stability.

How do PEM Fasteners prevent corrosion?

The corrosion resistance of PEM Fasteners is usually improved by surface treatment, such as galvanizing, nickel plating or coating. Different surface treatments can provide additional corrosion protection for fasteners, especially in humid or harsh environments. If there are strong corrosive media in the use environment, it is recommended to choose fasteners with high corrosion resistance surface treatment, or choose anti-corrosion materials such as stainless steel.

Do PEM Fasteners support mass production customization?

Yes, PEM Fasteners support mass production customization. According to customer needs, the size, thread type, material, surface treatment, etc. of the fasteners can be customized. Mass production usually reduces the cost of a single fastener and ensures consistency and quality in large-scale production.

Are PEM Fasteners suitable for use in the automotive industry?

A: PEM Fasteners are widely used in the automotive industry. They can be used to fix body parts, chassis, electronic systems, etc., especially in situations where fast and reliable installation is required. Due to the tight connection provided by PEM Fasteners, it can effectively cope with the vibration and friction generated by the car at high speeds.

How long is the life of M6 PEM Fasteners?

The life of M6 PEM Fasteners depends on their material, application environment and load conditions. For medium-load applications under normal use conditions, they can generally maintain long-term stability. Proper surface treatment and correct installation methods can significantly extend their service life. In high temperature, high humidity or highly corrosive environments, it is recommended to use specially designed high-durability PEM Fasteners.

Dongguan Qisheng Metal Technology Co., Ltd. is a professional manufacturer of screws and nuts and other fastener products integrating R&D, production, processing and sales. The company is located in the famous manufacturing city in China-Dongguan City, Guangdong Province. The company covers an area of 3,000 square meters.

Specializing in the production of special precision screws and nuts of various standards such as Chinese standard GB, Japanese standard JIS, British BS, American ANSI and ISO. Our equipment is advanced. At present, the smallest screw diameter that our company can produce is 0.4mm, the shortest is 0.4mm, and the longest is 300CM. The materials used are stainless steel SUS304 /SUS410/SUS 430 /SUS620, etc., red copper H95, brass C2700, aluminum 6061, titanium TI 04, etc.

Our products can meet the environmental testing standards of the European Union-ROHS, the United States–California 65 standard, Japan-SONY00259 etc., and even more stringent testing standards. At present, our salt spray test standard can reach up to 2000 hours, and the surface hardness can reach up to HV2000.

Our business policy is to serve every customer with the highest quality and fastest speed.

Please feel free to contact us if necessary.