2025-04-15 11:14:27

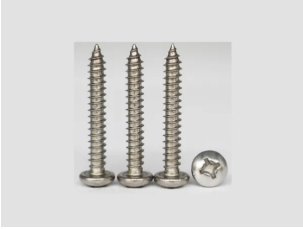

Pan Head Self Drilling Screws, also known as pan head self-drilling screws, are a kind of fasteners that integrate drilling and tapping. The tail of the screw is in the shape of a drill bit, which can drill holes on the surface of materials without pre-drilling holes and complete thread locking. The pan head is wide and flat, with stronger coverage and contact area.

Application:

Installation of building steel structures

Used for fixing metal roofing and wall panels, especially widely used in light steel villas and mobile houses.

Assembly of electrical housings

In the assembly process of household appliances, electrical boxes, electrical control cabinets and other products, it is widely used because of its fast installation and strong fastening force.

Sheet metal processing

It has a significant effect in the sheet metal connection of HVAC systems (heating, ventilation and air conditioning), automotive parts, and kitchen and bathroom equipment.

Furniture hardware

In modern panel furniture, the use of pan head self-drilling screws in parts with high connection strength requirements can ensure the stability of the overall structure.

Common materials:

Carbon steel (low carbon steel, medium carbon steel): commonly used in standard screws, the surface is electroplated.

Stainless steel (304, 316): Suitable for environments with high requirements for corrosion resistance, especially outdoor or humid environments.

Alloy steel: Used in engineering projects with higher strength requirements.

Features:

Strong self-drilling ability: The tail end is designed with a drill bit, which can penetrate thin steel plates, aluminum and other substrates without pre-drilling.

Integrated tapping: Self-tapping threads can be formed while drilling, simplifying the installation process and improving work efficiency.

Pan head design: The pan head structure makes it more suitable for occasions that require a flat appearance or clamping large-area connectors.

Multiple thread specifications: Common ones include ST2.9, ST3.5, ST4.2, ST4.8, etc., with fine pitch and strong locking force.

Rich surface treatment: Common treatment methods include galvanizing, nickel plating, Dacromet, colored zinc, etc., to enhance corrosion resistance.

High-speed operation compatibility: Suitable for high-speed equipment such as electric screwdrivers and impact screwdrivers, easy and quick installation.

Advantages:

Improve installation efficiency

Compared with the two-step operation of pre-drilling and screwing of traditional screws, Pan Head Self Drilling Screws can be completed in one step, shortening the installation time by more than 40%, which can significantly reduce the construction cost in large-scale projects.

Strong stability

When drilling, it forms a thread structure that fits tightly with the base material, reducing looseness or slipping, and is suitable for connecting parts of vibrating or mobile equipment.

Avoid material damage

For the structural optimization of metal sheets, the stress is evenly distributed during drilling to avoid material cracking or deformation.

Strong environmental adaptability

In the salt spray test, the galvanized products can last for more than 72 hours without red rust; Dacromet treatment can last for more than 500 hours, which is suitable for outdoor and humid and corrosive environments.

Applicable to a variety of base materials

It can be used for steel plates, aluminum plates, stainless steel plates, plastic plates, etc., with a wide range of industrial adaptability, especially in sheet metal, electrical installation, and construction.

FAQ:

What is the difference between Pan Head Self Drilling Screws and ordinary screws?

The biggest difference is that the tail has a drill bit design, which does not require pre-drilling and can be installed quickly; while ordinary screws need to be drilled first and then tapped or use self-Tapping Screw tools.

In what scenarios is stainless steel recommended?

It is recommended to use 304 or 316 stainless steel in outdoor, humid, and highly corrosive environments, especially for installation projects in coastal cities or chemical plants.

Are self-drilling screws suitable for thick plate connections?

Generally suitable for steel plates ≤6mm thick. After exceeding the thickness, the drill efficiency is significantly reduced. It is recommended to use special drilling for installation. For thicker connectors, multi-stage drilling structures or special screw solutions should be considered.

What appearance requirements are suitable for the Pan Head structure?

The pan head has a wide and flat surface, which is suitable for scenes that pursue a neat and beautiful installation surface, such as sheet metal edging, box structure, etc. It is less likely to damage the surface of the substrate than countersunk screws.

How to choose the surface treatment method?

For ordinary indoor use, electro-galvanizing treatment can be selected; for humid environments, colored zinc or Dacromet treatment is recommended; for scenes with high corrosion resistance requirements, stainless steel screws or special anti-corrosion coatings are recommended.