2025-02-15 16:35:07

What are CNC precision machined fasteners?

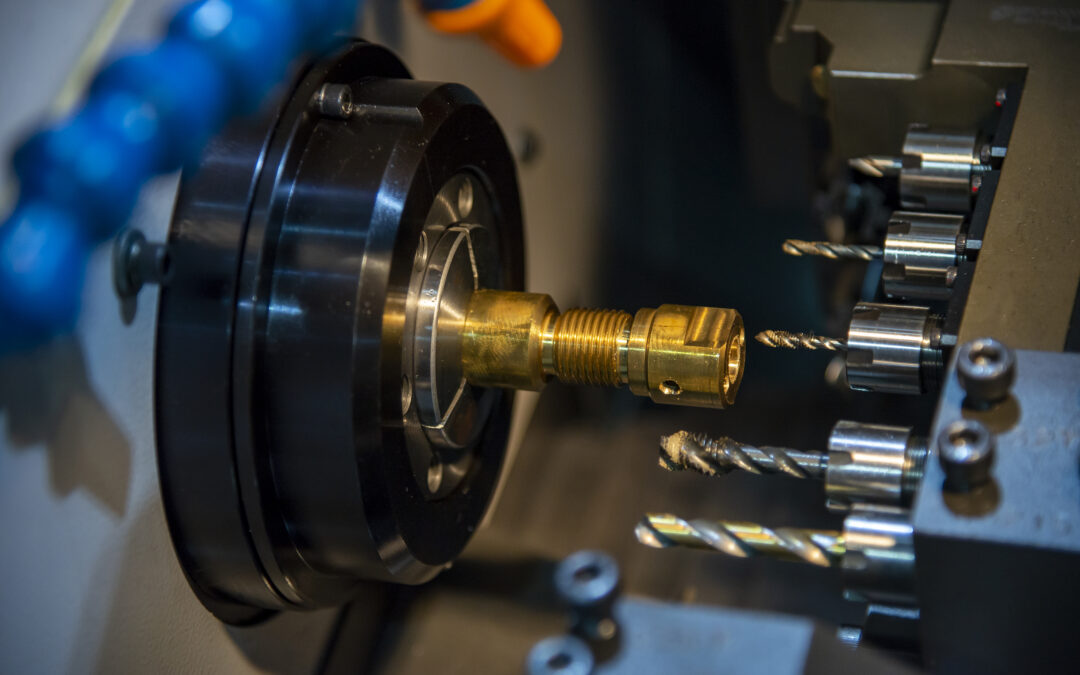

CNC precision machining is a manufacturing process that uses computer-controlled machines to perform precise operations on raw materials. In the production of fasteners, CNC machines are used to process fastener components such as screws, bolts, Nuts, washers, etc., through precise cutting, tapping and surface treatment to ensure that each fastener meets the required size, thread specifications and surface quality. Because CNC technology provides a high level of precision, it is ideal for manufacturing high-standard fasteners, especially for applications that require close tolerances.

Main advantages of CNC precision machined fasteners

CNC precision machining provides micron-level tolerances, which means that every screw, bolt or nut produced can perfectly match the mating component, ensuring its reliable performance.

CHEKSINE is able to achieve an accuracy of ±0.01 mm, providing customers with fasteners with threads and dimensions that fully meet the requirements to meet the needs of high-precision industrial applications.

Strong customization capabilities

Another significant advantage of CNC precision machining is the ability to customize fasteners according to customer needs. Whether it is a unique screw design, a specific pitch, or a non-standard material, CNC machines can accurately manufacture fasteners that meet the requirements according to programming. CHEKSINE provides a one-stop customized service from design to production to ensure that each product can meet the specific needs of customers.

Efficient production

Using CNC technology, the production process is highly automated, which not only reduces the errors caused by manual operation, but also shortens the production cycle. Compared with traditional manual processing, CNC precision processing has significantly improved production efficiency. CHEKSINE can complete the transition from small batch production to large-scale production in a short period of time, helping customers to enter the market faster.

Lower waste and cost

CNC processing technology can more accurately control the cutting and processing of materials and reduce material waste. Compared with traditional processing methods, CNC processing is more efficient, which can reduce the waste of raw materials and reduce production costs. This means that companies can obtain more competitive prices while maintaining high quality.

Excellent durability and performance

CNC processing can produce fasteners with high mechanical properties and corrosion resistance. Whether it is industrial equipment used in harsh environments or automotive parts that require high strength and wear resistance, CNC precision machining ensures the production of fasteners with excellent performance to meet the needs of various demanding applications.

CHEKSINE's production process

CHEKSINE's CNC precision machining fastener screw production process starts with design, using advanced CAD (computer-aided design) software for precise modeling. After the customer confirms the design plan, the CAD drawings will be transferred to the CNC machine for processing. Through high-precision milling, turning, tapping and other processes, fasteners such as screws and bolts are gradually formed. During the production process, all parts are strictly quality controlled and tested to ensure compliance with international standards.

In addition, CHEKSINE also uses high-quality materials for processing, including stainless steel, aluminum alloy, copper alloy, etc., to ensure that the processed fasteners have excellent mechanical properties and long-term reliability.

Industry trends and the future of CNC precision machining

With the continuous development of industrial technology, the market demand for customized and high-precision fasteners is increasing. Especially in high-tech industries such as automobiles, aerospace, and electronics, the requirements for fasteners are more stringent. In the future, CNC technology will continue to develop, and the level of automation and intelligence will continue to improve, which will provide more innovative solutions for fastener production.

At the same time, as the global environmental protection trend strengthens, companies have also begun to pay attention to the sustainability of fasteners. CNC precision machining can not only improve production efficiency, but also reduce material waste, helping companies achieve more environmentally friendly production goals.

With advanced technology and rich experience, CHEKSINE is committed to providing customers with high-quality, high-precision customized fastener screws to meet the needs of various industrial applications. Whether in automotive manufacturing, aerospace, or in the field of electronic products, CNC precision machining has become a key technology to ensure product quality and performance.