2024-11-30 16:59:29

Machine Screws are threaded fasteners designed to be used with Nuts or driven into a tapped hole in a workpiece. Stainless steel machine screws, specifically, are made from stainless steel alloys, which are known for their resistance to corrosion, rust, and staining. The composition of stainless steel typically includes iron, chromium, nickel, and other elements that enhance its strength and resistance to harsh conditions, such as moisture, chemicals, and high temperatures.

Unlike wood screws or sheet metal screws, machine screws have a uniform thread pitch and are designed to be used in precision applications where precise fastening is required. They come in a variety of sizes, lengths, and thread types, which are chosen based on the requirements of the specific application.

One of the key characteristics of stainless steel machine screws is their precision. To ensure that they meet the necessary standards for various applications, these screws are manufactured and measured with a high degree of accuracy.

Key aspects of precision measurement for stainless steel machine screws include:

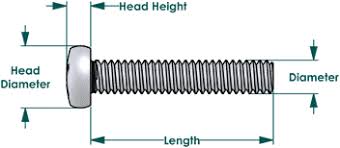

Thread Pitch and Diameter: The thread pitch refers to the distance between threads, and the diameter refers to the major diameter of the screw. Both must be measured accurately to ensure proper fit and function. Machine screws come in different thread types, such as Unified Thread Standard (UTS), metric threads (ISO), and others, depending on the application. Precision calipers, micrometers, and thread gauges are commonly used to measure the thread pitch and diameter.

Length: The length of a machine screw is measured from the underside of the head to the tip of the screw. Proper length is crucial for ensuring that the screw fits the tapped hole or the nut and engages fully for a secure fastening. Digital calipers or height gauges are often used to measure screw length precisely.

Head Type and Shape: The head of the screw may vary (e.g., flat, pan, hex, or countersunk) and needs to be measured to ensure that it fits the corresponding tool or application. The geometry of the head, such as the angle of countersunk heads, must also be consistent for precise insertion.

Thread Geometry: The angle, depth, and profile of the thread must be precisely manufactured for optimal engagement with the nut or tapped hole. Accurate thread measurement ensures proper performance and prevents thread stripping or failure during installation.

Surface Treatments of Stainless Steel Machine Screws

Stainless steel is inherently corrosion-resistant, but surface treatments can further enhance its properties, especially in aggressive environments. Various methods are used to improve the mechanical properties, aesthetics, and longevity of stainless steel machine screws.

Passivation: Passivation is a common treatment for stainless steel that involves applying an acid solution (often nitric acid) to remove free iron and other contaminants from the surface. This creates a thin, inert oxide layer that enhances the screw's corrosion resistance, particularly in highly corrosive environments like marine or chemical industries.

Electroplating and Coating: Stainless steel machine screws may be electroplated or coated with a variety of materials to improve their surface properties. Common coatings include:

Zinc Coating: Provides additional corrosion protection.

Nickel Plating: Increases wear resistance and provides a shiny, aesthetically appealing finish.

Black Oxide Coating: Provides corrosion resistance and a uniform dark finish without altering the dimensions of the screw.

Dacromet Coating: A corrosion-resistant coating that is often used for applications exposed to harsh outdoor environments, such as automotive or construction.

Anodizing (for aluminum-based alloys): Although not typically used for stainless steel, anodizing is a surface treatment applied to aluminum alloys to increase corrosion resistance and create a decorative color finish.

Polishing: Polishing enhances the appearance of stainless steel screws, giving them a smooth, reflective surface. This treatment also helps reduce friction and improves the screw’

s resistance to corrosion.

Lubrication: In some cases, stainless steel machine screws may be coated with lubricants to reduce friction and prevent galling (a form of surface wear). This is particularly useful when screws are tightened with high torque or in applications that involve frequent assembly and disassembly.

Applications of Stainless Steel Machine Screws

Due to their versatility and strength, stainless steel machine screws are used in a wide range of industries. Some of the most common applications include:

Automotive Industry: Stainless steel machine screws are used extensively in the automotive industry for fastening parts such as body panels, engine components, and electrical systems. Their resistance to rust and corrosion ensures the longevity of automotive parts, especially in exposed or harsh conditions.

Electronics and Electrical Industry: These screws are used in the assembly of electronic devices, circuit boards, and electrical housings. Stainless steel's ability to resist corrosion ensures that the screws retain their integrity over time, even in high-humidity environments.

Construction Industry: Stainless steel machine screws are frequently used in construction, particularly for structural components, metal framing, and HVAC systems. Their ability to withstand environmental stressors, such as moisture and extreme temperatures, makes them ideal for outdoor and indoor applications.

Food and Beverage Industry: Stainless steel is non-reactive, making it an ideal material for use in food processing machinery and equipment. Machine screws made from stainless steel are used to assemble processing machines, storage tanks, and conveyor systems.

Aerospace and Defense Industry: In aerospace and defense, stainless steel screws are used to assemble highly engineered systems where precision, reliability, and resistance to corrosion are crucial. These industries often require machine screws that meet exacting standards for strength, durability, and performance.

Medical Devices and Equipment: Stainless steel machine screws are commonly used in the medical industry for assembling surgical instruments, implants, and medical devices. Their biocompatibility and corrosion resistance are essential in ensuring the safety and longevity of medical equipment.

Maintenance of Stainless Steel Machine Screws

Proper maintenance of stainless steel machine screws is essential to ensure long-term performance, especially in demanding environments. Here are some key maintenance tips:

Regular Inspection: Machine screws should be regularly inspected for any signs of wear, damage, or corrosion. In some cases, screws may need to be replaced if they have been subjected to extreme loads, high temperatures, or corrosion.

Cleaning: Stainless steel screws should be cleaned regularly to remove dirt, debris, or other contaminants that can affect their performance. Cleaning can be done using mild detergents or solvents. Avoid using abrasive cleaning methods, which can damage the screw’s surface.

Lubrication: When installing stainless steel machine screws, it is often beneficial to apply a small amount of lubricant (such as anti-seize compound) to the threads. This helps to reduce friction and prevents the screws from seizing or becoming difficult to remove during future maintenance.

Avoid Over-Tightening: Over-tightening machine screws can lead to deformation of the screw or the material being fastened. Use a torque wrench to apply the recommended torque specification, ensuring a secure yet safe fastening.

Storage: Stainless steel screws should be stored in a dry, clean environment to prevent oxidation or contamination. If the screws are exposed to saltwater or harsh chemicals, immediate cleaning and maintenance should be performed.

Corrosion Monitoring: Even though stainless steel is resistant to corrosion, it is essential to monitor screws in critical applications (such as marine or chemical processing industries) for any signs of rust or pitting. In cases of heavy corrosion, the screws should be replaced to ensure the safety and integrity of the equipment.